The KLINGSPOR buffing wheel and compound line-up meets most needs for both cut buffing and color buffing. With a variety of stitch types and cotton materials, the KLINGSPOR program can benefit users in a range of production and fabrication environments. Both standard buffing wheel types and airway buffs are available to accomplish the cut or color tasks at hand.

Table of Contents

Polishing Wheels

Many KLINGSPOR products have a unique code to describe each product's key specifications. KLINGSPOR polishing wheels use the acronym, KPW, at the beginning of the item number to distinguish it from other abrasives. The following is an example of how to decipher item numbers of this type of product.

Example: KPWB1502520A1

KPW Materials

Cotton Treated

Cotton Treated is a material that has been chemically treated to add more aggression to the material. This material will help provide a fairly high finish.

Sisal

Sisal is the most aggressive material it is meant to cut. This coarse twine material will result in a dull finish.

Bramante

Bramante is the least aggressive material. Made of a type of twine, it is meant for strictly coloring a workpiece. This material will provide the brightest finish.

Sisal/Bramante

Sisal/Bramante is a combination of sisal and bramante material to give a mix of both cut and color. This material will provide a moderate finish.

Stitch Types

Spiral

Spiral polishing wheels are spirally sewn from the center to near the edge of the wheel. This type of stitch makes these wheels firm, and is excellent for cutting and polishing.

Concentric

This type of wheel is made of individual fabric sheets, sewn from the center in increments of space completely around the wheel. Typically 1/2” to 3/4” thick, and due to the type of the stitch, is a firm cutting and polishing product.

Loose

This type of wheel has a circle of stitches near the center of the wheel which allows the individual to work more freely. These polishing wheels are very flexible and soft, making them ideal for hard-to-reach and color buffing.

Airway Buffs

The following is an example of how to decipher item numbers of KLINGSPOR airway buffs. This type of product uses the acronym, AWB, at the beginning of the item number to distinguish it from other abrasives.

Example: AWBNWTFN4001274P

Only AIRWAY BUFFS are available with a 5 inch arbor ring and come in 14 inch and 16 inch wheels.

KPWREDUCT5TO1-1/2 STEEL REDUCTION 5" to 1-1/2"

AWB Materials

Cotton (B)

Cotton (Bramante) is the least aggressive material. Made of a type of twine, it is meant for strictly coloring a workpiece. This material will provide the brightest finish.

Cotton (C)

Cotton Treated is a material that has been chemically treated to add more aggression to the material. This material will help provide a fairly high finish.

NWT

Non-Woven is a special material focused on giving a bright finish, while removing some material at the same time, and is offered in different grits.

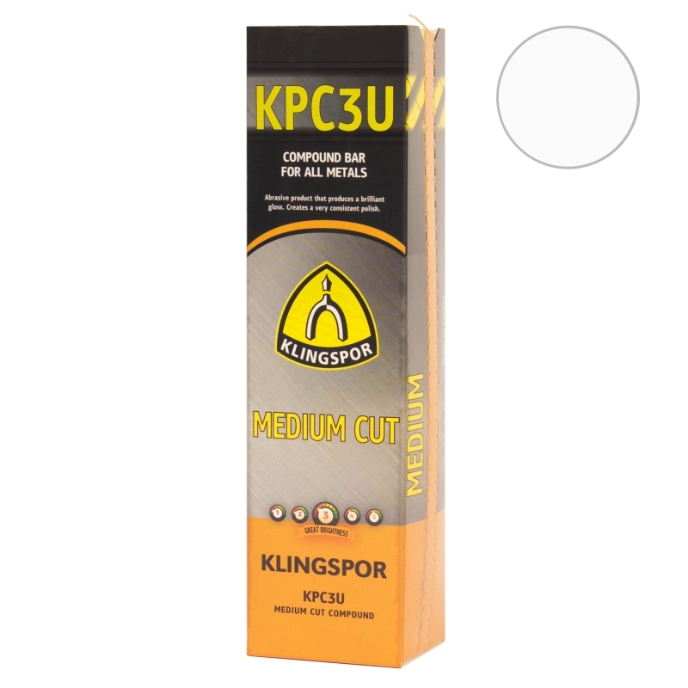

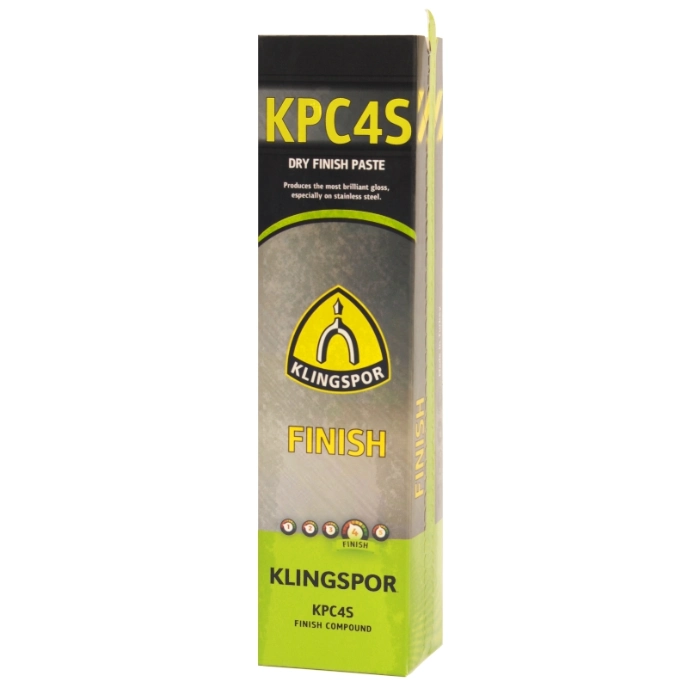

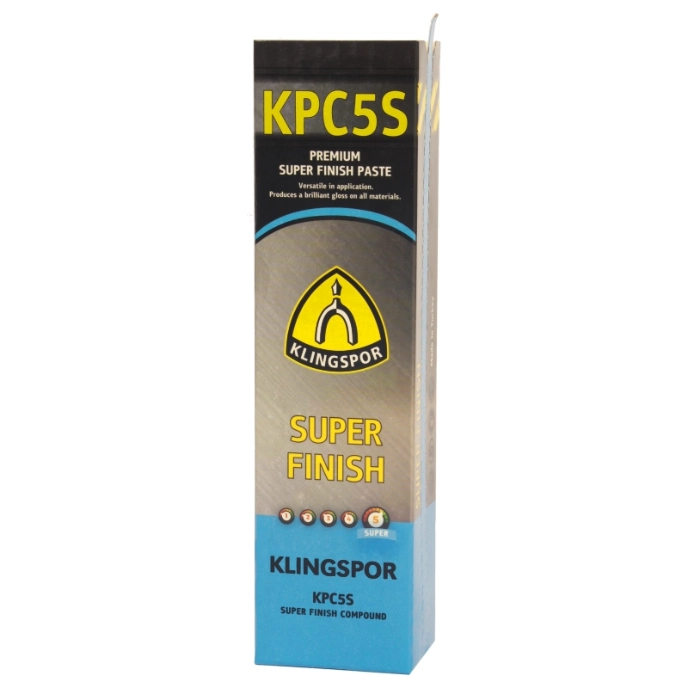

Polishing Compounds

KLINGSPOR's polishing compounds are materials that pair well with polishing wheels and airway buffs. They are special sticks of paste used for a greater cut and color. Coat the paste to the edges of wheels or buffs and apply to the workpiece to remove scratches, increase shine, and even leave a glossy appearance. Read the following information to determine which polishing compound best suits your project.

KPC2U

KPC3U

KPC4S

KPC5S

KPC4SF