Grinding Disc vs. Fibre Disc vs. SMT

Weld removal is an application that gives you choices. Often it's just a matter of preference, however, there are advantages to all three, flap disc, fibre disc and grinding disc.

The following chart compares the qualities of the A 24 R Grinding Disc, CS 565 Fibre Disc, and SMT 926 Supra.

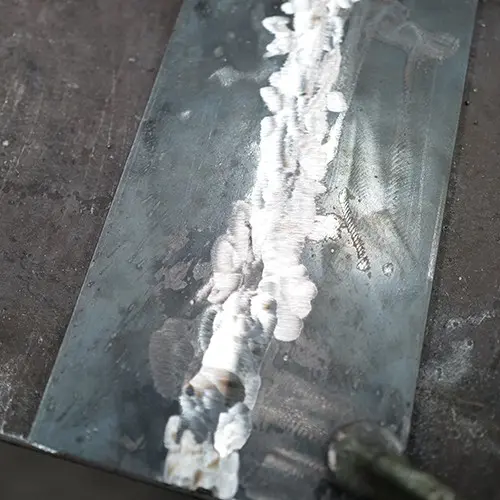

Example

Figure 1: A24R Grinding disc on metal surface. Line has several dents.

Figure 2: CS 565 fibre disc on metal surface. Several swirl marks can be seen.

Figure 3: SMT 926 disc on metal surface. Line is smoother with less marks.